Micro capillary tubes trace their roots to initially being designed for specific laboratory applications, and these tubes underwent a transformative journey with technological advancements. The marriage of precision engineering and technological progress catapulted micro capillary tubes into mainstream manufacturing. These tubes are not mere conduits but precision instruments shaping industries.

Table of Contents

- 1 Introduction

- 2 The importance of micro capillary tubes in advanced manufacturing

- 3 Applications of micro capillary tubes in various industries

- 4 Advantages of using microcapillary tubes in manufacturing processes

- 5 The manufacturing process of micro capillary tubes

- 6 Choosing the suitable material for micro capillary tubes

- 7 Quality control and testing of microcapillary tubes

- 8 Innovations and advancements in micro capillary tube technology

- 9 Successful implementation of micro capillary tubes in manufacturing

- 10 Conclusion: The future of micro capillary tubes in advanced manufacturing

- 11 FAQs

- 11.1 What industries benefit most from micro capillary tubes?

- 11.2 How do micro capillary tubes contribute to sustainability?

- 11.3 Are there any limitations to the use of micro capillary tubes?

- 11.4 What role do micro capillary tubes play in quality assurance?

- 11.5 Can manufacturers optimize the use of micro capillary tubes for cost efficiency?

Introduction

One such technology that has gained significant attention is micro capillary tubes. These tiny tubes, often as thin as a human hair, are revolutionizing advanced manufacturing processes across various sectors.

Micro capillary tubes are crucial in delivering precise quantities of fluids, gases, and electrical signals in industrial applications. Their microscopic size and versatility make them ideal for microfluidics, where small volumes of liquids are manipulated and controlled with exceptional precision. This technology finds applications in fields such as pharmaceuticals, biotechnology, electronics, and medical diagnostics, to name a few.

Their ability to accurately distribute minute amounts of liquid and perform complex tasks with high efficiency has made micro capillary tubes indispensable in research laboratories and industrial settings. By enabling precise control and reducing waste, these tubes contribute to cost-effective manufacturing processes and improved product quality.

We delve into the various applications of micro capillary tubes and explore their transforming role in advancing manufacturing technologies. Join us as we uncover how this small but powerful technology is shaping the future of industries worldwide.

The importance of micro capillary tubes in advanced manufacturing

Various industries utilize micro capillary tubes, from pharmaceuticals to electronics. These tubes facilitate the delivery of precise amounts of liquid, and their small size enables a higher degree of accuracy compared to traditional methods of fluid delivery. Additionally, micro capillary tubes find application in microfluidics, a field that entails manipulating and controlling small volumes of liquid. This technology finds applications in fields such as pharmaceuticals, biotechnology, electronics, and medical diagnostics, to name a few.

Micro capillary tubes have several advantages over traditional fluid delivery methods. They enable precise control and reduce waste, contributing to cost-effective manufacturing processes and improved product quality. They also allow for delivering small amounts of liquid, making them ideal for microfluidics and other applications where precision is crucial. The small size of micro capillary tubes also means that they can be used in applications where space is limited.

Applications of micro capillary tubes in various industries

Micro capillary tubes are used in many industries, including pharmaceuticals, biotechnology, and electronics. In the pharmaceutical industry, micro capillary tubes deliver precise amounts of drugs to patients, reducing the risk of overdose and side effects. In biotechnology, micro capillary tubes are used to manipulate and control small volumes of liquids, allowing new therapies and treatments to be developed.

Micro capillary tubes deposit tiny amounts of conductive or insulating materials onto electronic components. This process is essential in the manufacturing of microchips and other electronic devices. Micro capillary tubes are also used in medical diagnostics, where they are used to collect and analyze small amounts of blood or other bodily fluids.

Advantages of using microcapillary tubes in manufacturing processes

Micro capillary tubes offer several advantages over traditional fluid delivery methods. One of the main advantages is their ability to deliver precise amounts of liquid. This precision is essential in many industries, including pharmaceuticals and biotechnology, where the accuracy of dosages is critical. Microcapillary tubes also reduce waste, as they can deliver precise amounts of liquid without excess.

Another advantage of micro capillary tubes is their versatility. Various applications can utilize them, ranging from microfluidics to electronics. Their small size also allows their application in settings where space is limited. Additionally, micro capillary tubes prove easy to use, integrating seamlessly into manufacturing processes with minimal disruption.

The manufacturing process of micro capillary tubes

The manufacturing process of micro capillary tubes is complex and requires precision and accuracy. The tubes are typically made from glass, quartz, or plastic and are produced using various techniques, including extrusion, etching, and laser drilling.

Extrusion involves heating and forcing the material through a die to form a tube. Etching involves using a chemical solution to dissolve the fabric and create the desired shape. Laser drilling consists of using a laser to make holes in the material.

Once the tubes form, they undergo cleaning and polishing to eliminate imperfections. Quality control plays an essential role in the manufacturing process, with inspectors examining each box to verify its compliance with the required specifications.

Choosing the suitable material for micro capillary tubes

The material used to make microcapillary tubes is crucial, as it affects the performance and durability of the tubes. Glass is a popular choice for micro capillary tubes, as it is transparent and has excellent chemical resistance. Quartz is also commonly used, as it has excellent thermal stability and can withstand high temperatures.

Another material used for crafting micro capillary tubes is plastic. Plastic, being lightweight and moldable into complex shapes, proves ideal for specific applications. However, plastic is less durable than Glass or quartz, and it may not be suitable for some applications.

Quality control and testing of microcapillary tubes

Quality control is an essential part of the manufacturing process for microcapillary tubes. Each tube is inspected to ensure it meets the specifications for diameter, length, and other characteristics.

Testing is also an essential part of the quality control process. Medial micro blood collections tubes are tested for their ability to deliver precise amounts of liquid and their durability and resistance to chemical and thermal stress.

Innovations and advancements in micro capillary tube technology

The field of micro capillary tube technology is in a constant state of evolution, with innovations and advancements consistently occurring. One of the most significant advancements in recent years is the development of microfluidic devices. These devices integrate microcapillary tubes with other components, such as pumps and valves, to create complete microfluidic systems.

Other innovations include developing new materials for microcapillary tubes, such as carbon nanotubes and graphene. These materials offer unique properties, such as high electrical conductivity and mechanical strength, which may make them suitable for specific applications.

Successful implementation of micro capillary tubes in manufacturing

Microcapillary tubes have found successful implementation in numerous manufacturing processes, delivering significant benefits in terms of precision, quality, and cost-effectiveness.

One example is the use of micro capillary tubes in manufacturing microchips. Microcapillary tubes deposit tiny amounts of conductive or insulating materials onto electronic components, enabling the precise control of electrical properties. This process has revolutionized the manufacturing of microchips, making it possible to produce smaller and more complex devices.

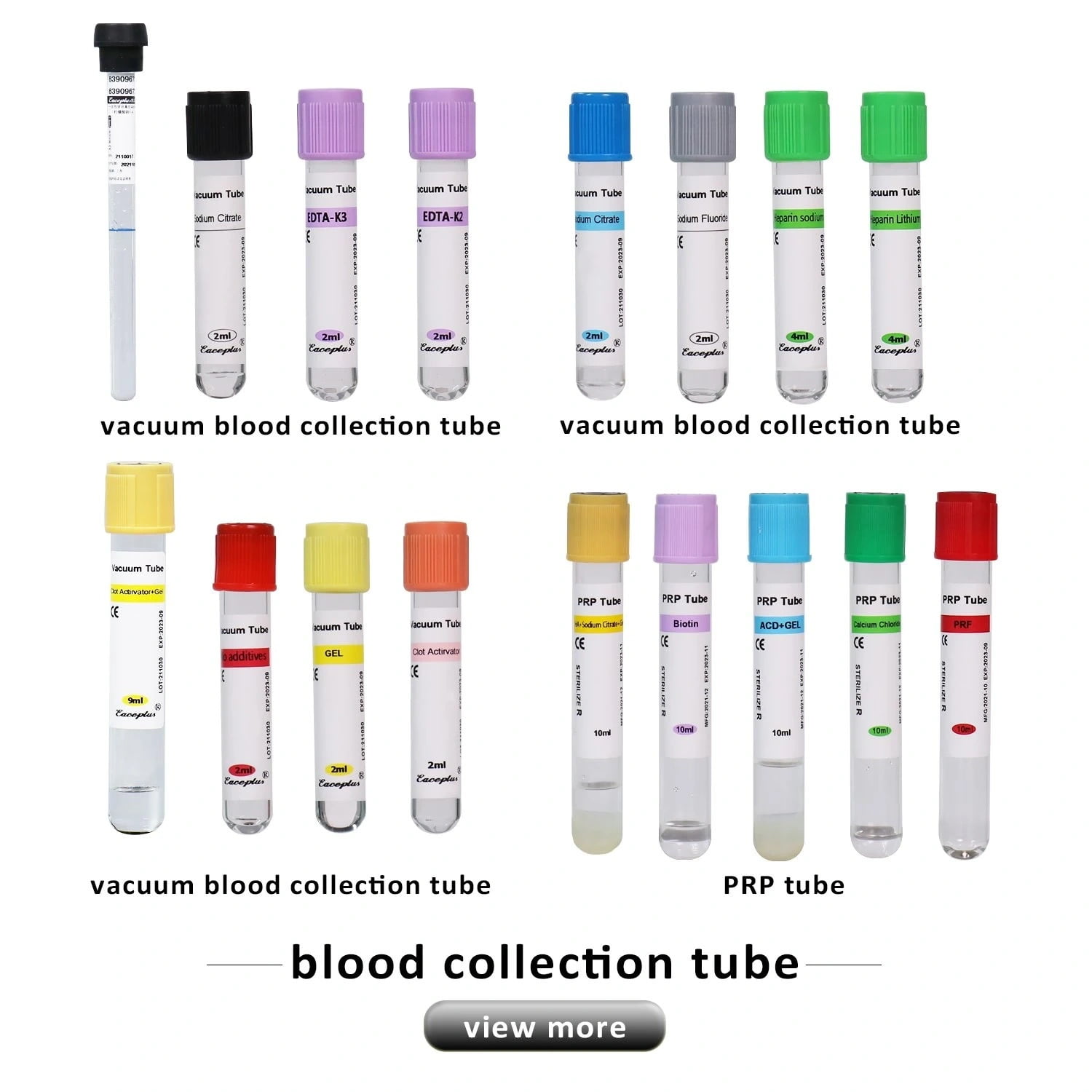

| Logo Printing: | With Logo Printing |

| Material: | Plastic |

| Quality Guarantee Period: | Two Years |

| Ethylene Oxide Sterilization: | Ethylene Oxide Sterilization |

| Type: | Test Strips & Test Tube |

| Usage: | Disposable Blood Collection |

| Trademark: | Eaceplus |

| Group: | Adult |

Another example is the use of micro capillary tubes in medical diagnostics. Micro capillary tubes collect and analyze small amounts of blood or other bodily fluids, enabling the early detection of diseases and conditions.

Conclusion: The future of micro capillary tubes in advanced manufacturing

The future of micro capillary tubes in advanced manufacturing shines brightly as constant innovations and advancements propel it forward. This technology provides substantial benefits in terms of precision, quality, and cost-effectiveness. Its versatility ensures utilization across a wide range of applications.

As manufacturing processes become more complex and demanding, micro capillary tubes will continue to be critical in driving innovation and transforming industries. From pharmaceuticals to electronics, microcapillary tubes are shaping the future of industries worldwide.

FAQs

What industries benefit most from micro capillary tubes?

Microcapillary tubes find applications in various industries, including healthcare, electronics, and precision engineering. Their versatility makes them invaluable across diverse manufacturing processes.

How do micro capillary tubes contribute to sustainability?

Micro capillary tubes play a crucial role in sustainable manufacturing practices by minimizing waste and optimizing resource usage. Their efficiency aligns with the global push for environmentally conscious production.

Are there any limitations to the use of micro capillary tubes?

While highly versatile, micro capillary tubes face challenges in precision and manufacturing complexities. Ongoing research aims to address these limitations and further enhance their capabilities.

What role do micro capillary tubes play in quality assurance?

Micro capillary tubes ensure consistency in manufacturing by delivering precise fluid control. This contributes to the quality assurance process, crucial in industries where precision is paramount.

Can manufacturers optimize the use of micro capillary tubes for cost efficiency?

Manufacturers can optimize the economic benefits of micro capillary tubes by investing in advanced manufacturing techniques quality control measures, and leveraging their ability to minimize waste and enhance efficiency.