Introducing the Eco-Friendly of No-Additive Tubes by SinymedicalIn today’s fast-paced world, where sustainability and eco-consciousness are gaining more importance, Sinymedical presents a groundbreaking solution: the No-Additive Tube. This innovative product revolutionizes the medical industry and contributes to a greener and more environmentally friendly future.

The Sinymedical No-Additive Tube, known as the Eco-Friendly Marvel, is a game-changer in medical tubes. Unlike traditional lines, which often contain additives and chemicals that can harm the environment, these tubes are siny manufactured with a focus on sustainability and eco-friendliness.

Table of Contents

What is a No-Additive Tube?

A no-additive, additive-free, or additive-exempt tube is a revolutionary packaging solution that challenges traditional manufacturing practices. Unlike conventional lines, which often incorporate additives for various purposes, no-additive pipes are crafted without these additional chemicals. This innovative approach relies on the inherent properties of the materials themselves, resulting in a packaging solution that is both environmentally friendly and consumer-conscious.

Composition and Manufacturing

No-additive tubes are typically composed of a single material or a combination of materials inherently possessing the required characteristics for effective packaging. These materials are carefully chosen to meet the specific needs of the product being packaged. By avoiding additives, which can include colorants, stabilizers, and preservatives, no-additive tubes offer a cleaner and more sustainable alternative.

Understanding No-Additive Tubes

No-additive tubes, often called additive-free or additive-exempt tubes, are a revolutionary product that challenges traditional manufacturing practices. Unlike their conventional counterparts, these tubes are fabricated without additives, often harmful chemicals contributing to pollution and environmental degradation. Instead, no-additive lines are crafted using innovative techniques that rely on the inherent properties of the materials themselves, resulting in a greener and more sustainable production process.

The Environmental Impact

Traditional tube manufacturing heavily relies on additives to achieve desired properties, colors, and textures. However, this reliance comes at a cost to the environment, as the production and disposal of these additives contribute to pollution, resource depletion, and landfill accumulation. No-additive tubes eliminate this negative impact by reducing the need for additives, leading to cleaner production and less waste. This shift benefits the environment and aligns with consumer demand for eco-friendly products.

Benefits of No-Additive Tubes

No-additive tubes offer many benefits, contributing to their growing popularity and significance in various industries. These benefits extend beyond their eco-friendly composition, making them a preferred choice for manufacturers and consumers.

Environmental Sustainability

The most notable advantage of no-additive tubes is their positive environmental impact. By eliminating the need for harmful additives in the manufacturing process, these tubes significantly reduce pollution and release toxins into the ecosystem. This translates to a reduced carbon footprint and a more sustainable planet.

Reduced Plastic Waste

Traditional tubes often incorporate layers of plastic and other materials, making them challenging to recycle. In contrast, no-additive lines are designed with simplicity in mind. Their composition typically consists of a single material, making them easier to recycle and reducing plastic waste.

Enhanced Consumer Safety

Additives used in conventional tube manufacturing can sometimes migrate into the products they contain, posing potential health risks to consumers. No-additive tubes eliminate this concern, providing a safer option for packaging food, cosmetics, pharmaceuticals, and other sensitive products.

Innovation in Design

The shift towards no-additive tubes has spurred innovation in tube design. Manufacturers are exploring new shapes, sizes, and dispensing mechanisms, creating opportunities for more convenient and user-friendly packaging solutions. This focus on design innovation enhances the overall consumer experience.

Alignment with Consumer Values

As consumers become more environmentally conscious, their purchasing decisions are influenced by sustainability factors. No-additive tubes cater to this growing demand for eco-friendly products, allowing manufacturers to appeal to a broader customer base and foster brand loyalty.

Versatility Across Industries

No-additive tubes have applications in diverse industries, including cosmetics, pharmaceuticals, food, etc. Their adaptability and versatility make them ideal for packaging a wide range of products, showcasing their universal appeal.

Long-Term Cost Efficiency

While the initial production costs of no-additive tubes might be slightly higher due to the innovative manufacturing process, the long-term benefits offset this investment. Reduced waste disposal costs, increased consumer trust, and potential regulatory advantages make these tubes a cost-effective choice in the long run.

Regulatory Compliance

No-additive tubes often align with evolving regulations and standards related to sustainable packaging. Manufacturers who adopt these tubes position themselves favorably in terms of compliance, positioning their products for success in an increasingly regulated market.

The benefits of no-additive tubes extend far beyond their environmentally friendly composition. From reduced plastic waste and enhanced consumer safety to innovation in design and cost efficiency, these tubes are reshaping industries and setting new standards for sustainability. As manufacturers and consumers recognize their advantages, no-additive tubes are poised to play a significant role in shaping a greener and more conscientious future.

Applications of No-Additive Tubes

No-additive tubes’ versatility and eco-friendly nature have led to their adoption across a wide range of industries. These innovative tubes are revolutionizing how products are packaged, stored, and distributed, offering unique advantages that cater to specific industry needs. Let’s explore some of the key applications of no-additive tubes:

Cosmetics and Personal Care

No-additive tubes have a significant place in the cosmetics and personal care industry. They are used to package various products, including creams, lotions, serums, and even makeup. The no-reactive nature of these tubes ensures that the integrity of the product remains intact, preserving its quality and effectiveness.

Pharmaceuticals and Healthcare

Maintaining product integrity is paramount in the pharmaceutical and healthcare sectors. No-additive tubes are ideal for packaging medications, ointments, and medical creams. Their hygienic composition ensures that the products remain uncontaminated and safe for use.

Food and Beverages

The food industry is embracing no-additive tubes for packaging condiments, sauces, spreads, and other food products. These tubes help keep the contents fresh, safe, and free from potentially harmful additives. No-additive lines also reduce food waste by preserving the quality of perishable items.

Household and Cleaning Products

No-additive tubes are making their way into the household and cleaning product sectors. They are used to package various items such as hand sanitizers, detergents, and cleaning gels. The absence of harmful additives aligns with consumer preferences for safe products for their homes and the environment.

Industrial and Chemicals

Industries dealing with chemicals and industrial products are also benefiting from no-additive tubes. These tubes can safely contain and dispense various substances, including adhesives, sealants, and industrial lubricants. The lack of additives ensures that the purity of these substances is maintained.

Automotive and Lubricants

No-additive tubes find a valuable role in the automotive sector. They are used to package lubricants, additives, and fluids essential for the proper functioning of vehicles. The tubes’ reliability and no-contaminating properties contribute to the performance and longevity of automotive products.

Arts and Crafts

In the arts and crafts industry, no-additive tubes are used for packaging various creative materials such as paints, glues, and dyes. Artists and crafters appreciate the tubes’ precision dispensing and the assurance that their products are free from harmful additives.

Pet Care

No-additive tubes are also making their way into the pet care industry. From packaging pet shampoos to medicinal creams, these tubes offer a safe and hygienic way to store and distribute products that come into contact with pets’ sensitive skin and fur.

Personal Hygiene and Toiletries

Items like toothpaste, hand creams, and personal hygiene products benefit from no-additive tubes. The tubes’ composition ensures that the products remain free from contamination, providing consumers with safe and effective options for their personal care routines.

No-additive tubes are transforming the way products are packaged and consumed across a wide spectrum of industries. Their versatility, safety, and eco-friendly characteristics make them an essential tool for manufacturers aiming to meet consumer demands for sustainable and responsible packaging solutions. As industries continue to innovate and adapt, no-additive tubes will likely play an increasingly integral role in shaping the future of packaging.

Advantages of No-Additive Tubes

No-additive tubes offer a range of benefits that make them a preferred choice in various industries. Their unique composition and innovative manufacturing process give rise to advantages catering to environmental concerns and consumer demands. Let’s explore the key benefits of no-additive tubes:

Environmental Sustainability

The foremost advantage of no-additive tubes is their positive impact on the environment. Traditional tube manufacturing often relies on additives, contributing to pollution and environmental degradation. No-additive lines eliminate the need for these harmful chemicals, resulting in a greener and more sustainable production process. This aligns with the growing global emphasis on reducing carbon footprints and minimizing waste.

Reduced Carbon Footprint

By eliminating additives, no-additive tubes contribute to a reduced carbon footprint throughout their lifecycle. The absence of additives in both the production and disposal stages reduces greenhouse gas emissions and conserves resources, making these tubes an environmentally responsible choice.

Safer Product Packaging

Additives in traditional tubes can sometimes migrate into the products they contain, posing health risks to consumers. No-additive lines offer a safer packaging option by eliminating the potential for harmful chemicals to leach into the contents. This is especially crucial for products in industries such as cosmetics, pharmaceuticals, and food, where consumer safety is paramount.

Enhanced Consumer Appeal

As consumer awareness of environmental issues grows, there is a heightened demand for sustainable products. No-additive tubes resonate with environmentally conscious consumers, allowing manufacturers to appeal to a wider audience. Brands prioritizing sustainability often establish stronger connections with their customers, increasing loyalty and trust.

Innovation in Design

No-additive tubes encourage innovation in packaging design. Manufacturers are pushed to explore new shapes, sizes, and dispensing mechanisms to enhance the user experience. This drive for innovation results in more convenient and user-friendly packaging solutions that cater to evolving consumer needs.

Versatility Across Industries

No-additive tubes find applications in various industries, showcasing their versatility. From cosmetics and pharmaceuticals to food and industrial products, these tubes offer a solution that spans diverse sectors. This adaptability makes them a valuable asset for manufacturers seeking sustainable packaging options.

Cost-Effectiveness

While there might be a slight initial increase in production costs due to innovative manufacturing processes, no-additive tubes often offer long-term cost benefits. Reduced waste disposal costs, increased consumer trust, and alignment with sustainability trends can improve brand perception and lead to financial savings.

Regulatory Compliance

No-additive tubes align with the evolving regulatory landscape focused on sustainable packaging practices. Manufacturers who adopt these tubes position themselves favorably in compliance, demonstrating their commitment to responsible and eco-friendly production methods.

Positive Industry Impact

The adoption of no-additive tubes contributes to positive changes within industries. It encourages other manufacturers to prioritize sustainability, fostering a more environmentally conscious marketplace. This collective shift toward eco-friendly practices can significantly impact local communities and the global ecosystem.

No-additive tubes offer a multitude of advantages that extend beyond their eco-friendly composition. From reduced environmental impact and enhanced consumer safety to design innovation and cost-effectiveness, these tubes pave the way for a more sustainable and responsible future. As industries continue to evolve, no-additive lines stand as a testament to the power of innovation in addressing pressing environmental challenges.

Additionally, Sinymedical’s No Additive Tube significantly reduces waste in the healthcare system. The production and disposal of traditional tubes with additives contribute to the accumulation of medical debris, threatening the environment. With the eco-friendly design of Sinymedical’s No Additive Tube, healthcare facilities can actively participate in sustainable practices and decrease their environmental footprint.

Not only does the No Additive Tube benefit patients and healthcare providers, but it also aligns with Sinymedical’s commitment to corporate social responsibility. in medical, it understands the importance of preserving the environment for future generations, and the development of the No Additive Tube is just one example of their dedication to sustainable innovation.

Conclusion No Additive Tube

In conclusion, Sinymedical’s No Additive Tube is a game-changer in the medical industry. By prioritizing patient safety and reducing environmental impact, this eco-friendly solution transforms how blood collection and testing are conducted. Healthcare professionals can now provide top-quality care while actively participating in sustainable practices. Join Sinymedical in their mission to create a greener future with the No Additive Tube.

FAQs No Additive Tube

1. What is a no-additive tube?

A no-additive tube is a type of cylindrical structure that is manufactured using a process that minimizes or eliminates the use of additives. Additives are substances typically mixed with materials to enhance their properties or performance. In manufacturing, no-additive refers to the absence or reduction of these additional substances in the production process of tubes.

2. Which tube is a no-additive tube?

A no-additive tube is a type of tube that is manufactured without the use of additives. Additives are substances typically added to materials during manufacturing to enhance their properties or characteristics. No-additive lines are produced using simpler processes that do not involve the incorporation of these extra substances.

3. Which blood tube has no additives?

The blood tube that typically has no additives is called a “Red Top” or “Plain Tube.” This tube type collects blood samples without any additives or anticoagulants. It allows the blood to clot naturally, and the serum or plasma can be separated from the clotted blood for various laboratory tests. The absence of additives in these tubes ensures that the collected sample remains in its natural state, which is crucial for certain diagnostic procedures.

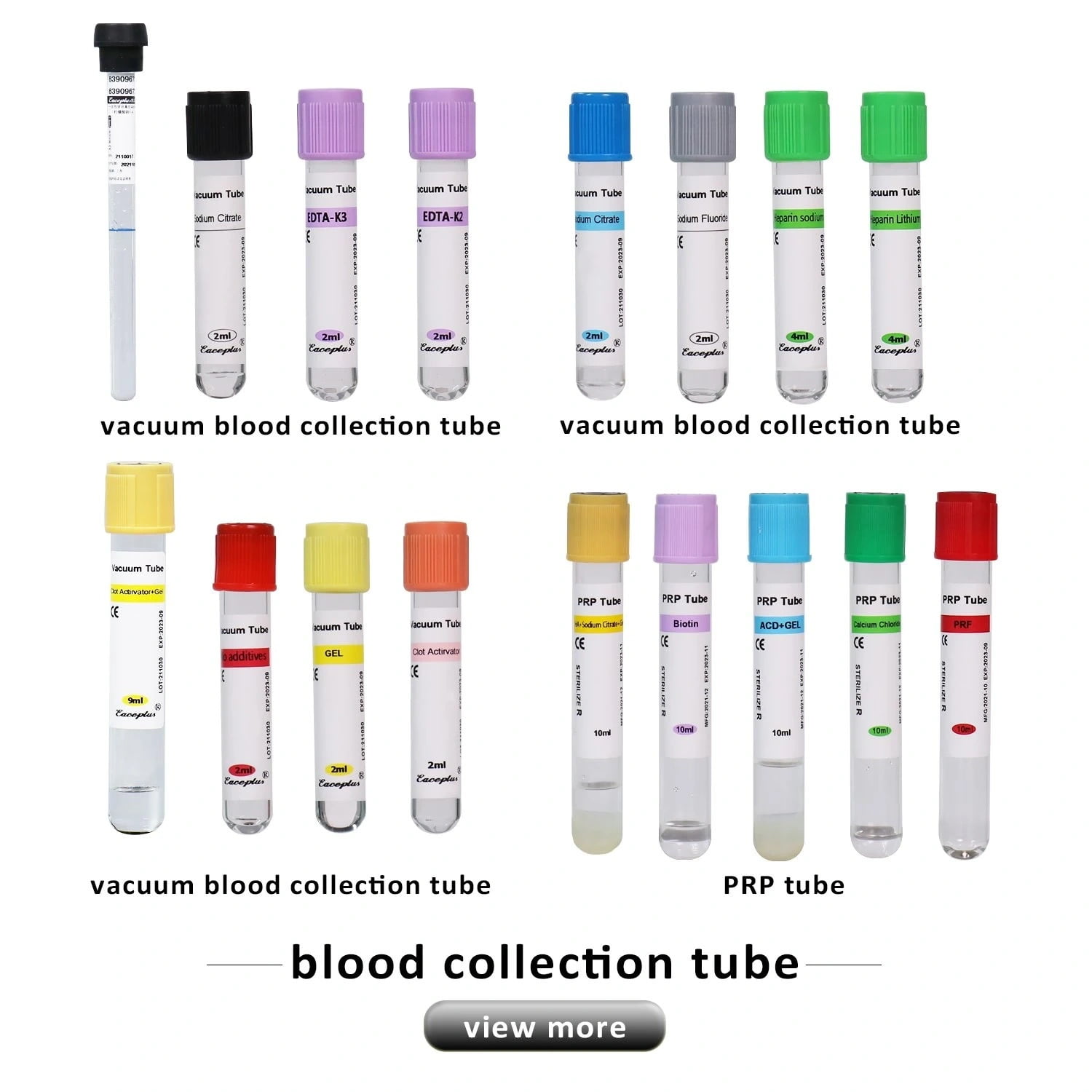

4. What are additive tubes?

Additive or additive-containing tubes are specialized containers used in medical and laboratory settings to collect blood samples for diagnostic testing. These tubes are designed to include specific additives or anticoagulants within them. These additives serve various purposes, such as preventing blood from clotting, preserving the integrity of blood components, or enhancing the accuracy of certain tests.

5. How many times do you invert no-additive tubes?

No-additive tubes, also known as plain tubes or red-top tubes, typically do not contain any anticoagulants or additives. These tubes are used for collecting blood samples that require clotting and are commonly used for serum testing. Unlike additive lines that need specific inversion to mix blood with additives, no-additive lines do not have a particular requirement of inversion.

6. What is a no additive tube used for?

These tubes are specifically designed for tests requiring blood to clot naturally. The absence of additives in these tubes ensures that the collected blood remains in its original state, allowing for accurate analysis of serum components.

7. What color is the top of a no additive tube?

The top of a no-additive blood collection tube is typically red. The red top indicates that the line contains no additives or anticoagulants. No-additive tubes are used for collecting blood samples that require natural clotting, allowing for the separation of serum from the clotted blood components. The absence of additives in these tubes ensures that the collected blood remains in its original state, making them suitable for various diagnostic tests that rely on serum analysis.