We typically work as a hands-on team to guarantee that we will provide you with the best quality and price for medical ECG paper, 50mmx20m ECG Paper Rolls, and ECG paper 50×30.5 and that we can provide various specifications for ultrasound gel and econometrics 170 fetal monitor paper. Do not hesitate to contact us if you have any more questions. We appreciate your support, which never stops motivating us.

The product will be shipped to locations across the globe, including Sheffield, Rotterdam, Poland, America, Australia, and Guyana. To meet your particular needs and specifications, we also offer OEM service. We cherish every chance to give our clients the most excellent products possible, and we have a solid staff of skilled engineers who specialize in hose design and development.

Table of Contents

- 1 Introduction to Medical ECG Paper

- 2 How to Read ECG Paper?

- 3 The Significance of Medical ECG Paper

- 4 ECG Paper Manufacturers and Suppliers

- 5 The Manufacturing Process

- 6 What Are the Different Types of ECG Paper?

- 7 Why Use an ECG Paper instead of Ordinary Paper?

- 8 Ensuring Regulatory Compliance in ECG Paper Production

- 9 What Should I Look for in an ECG Paper?

- 10 Final Thoughts

- 11 FAQs: ECG Paper

Introduction to Medical ECG Paper

Electrocardiography (ECG) plays a pivotal role in diagnosing cardiac abnormalities. However, the accuracy of ECG readings heavily relies on the quality of the ECG paper used during the procedure.

What is an ECG Paper?

E.C.G. Paper is a specialized paper used for recording signals in the machine for electrocardiograms employed in cardiac research. The production of this paper can be profitable on a small scale since it doesn’t demand significant investments in technology and plants. Hospitals and specialist practices require high-quality ECG paper for reliable diagnoses and accurate results.

How to Read ECG Paper?

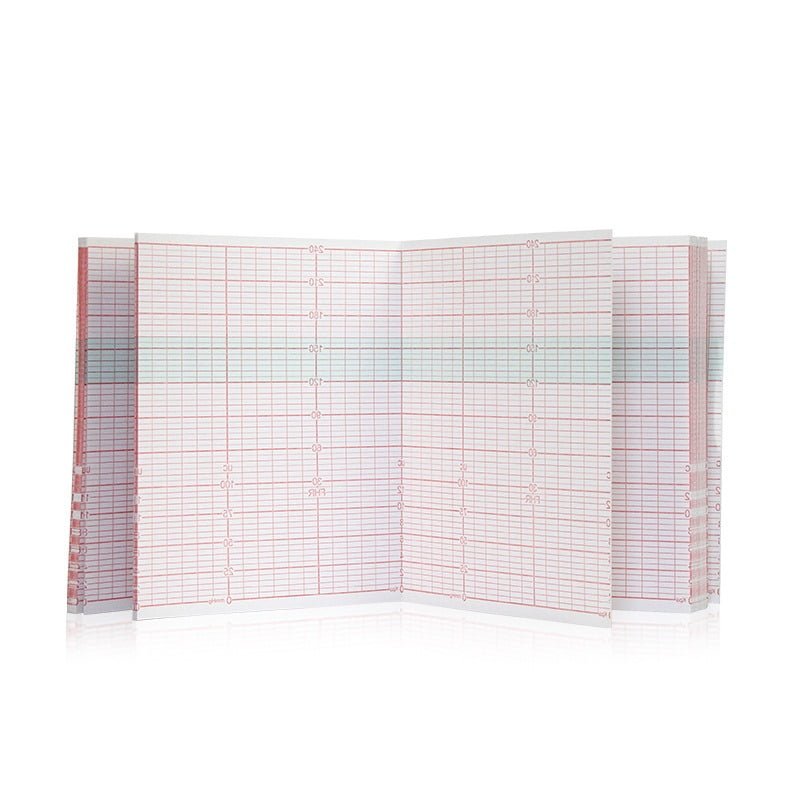

Finding the rate and anomalies of the electrical impulses traveling through the heart are the three main goals of the ECG exam paper is the first step in reading an ECG strip. The most critical characteristics are the little boxes on the page with the numbers and letters labeled.

The ECG paper is covered in tiny squares corresponding to a distinct period. The ECG machine’s make and model can affect the number of squares per second; however, it usually falls between 25 and 50. Locate the baseline, or the flat line at the bottom of the tracing, before reading an ECG paper.

The Significance of Medical ECG Paper

The role of ECG paper manufacturers and suppliers is crucial to understanding the pivotal role that ECG paper plays in the healthcare ecosystem. ECG paper serves as the canvas upon which the heart’s electrical activity is translated into visual data.

ECG Paper Manufacturers and Suppliers

Medical ECG paper manufacturers and suppliers are the unsung heroes behind the scenes, ensuring healthcare providers can access top-quality ECG paper for their diagnostic needs. These specialized companies are dedicated to producing ECG paper that meets the highest precision, sensitivity, and durability standards.

Quality Assurance and Product Range

Company A’s proven track record an ECG paper supplier emphasizes quality assurance and offers a comprehensive range of ECG paper products to meet varying clinical needs.

Innovation in ECG Paper Technology

Company B pioneers innovation in ECG thermal paper roll technology, incorporating advancements such as anti-static properties and enhanced print contrast for superior diagnostic accuracy.

Global Reach and Customer Satisfaction

Renowned for its global reach and commitment to customer satisfaction, Company C ensures prompt delivery and responsive support services, fostering long-term partnerships with healthcare providers worldwide.

The Manufacturing Process

The production of medical ECG paper is an intricate process that demands precision and attention to detail. Manufacturers adhere to stringent quality standards to ensure the paper meets the performance requirements for accurate ECG readings. The process typically involves:

- Sourcing high-quality paper material.

- Applying a conductive coating.

- Undergoing precision cutting and packaging.

The coating is critical, as it allows the paper to record the heart’s electrical impulses effectively during ECG procedures. Manufacturers utilize advanced technology and comprehensive testing to guarantee the reliability and consistency of their ECG paper products.

| Product Name | E.C.G Paper |

| Material | 100% Wood Pulp |

| Paper Type | Thermal Paper |

| OEM/ODM | Yes |

| Certificate | CE, ISO13485, ISO9001 |

| Usage | Medical |

| Package | Customizable |

| Sample | Contact Us |

| Service | The groups we serve are: distributors, import traders, government procurement, buying agents, and medical chain stores. we provide one-stop procurement for you to simplify your procurement process |

What Are the Different Types of ECG Paper?

ECG paper is the canvas for sinymedical imaging, capturing vital cardiac rhythms. It is available in several designs, such as roll, Z-fold, and grid, each tailored for a particular ECG machine and level of diagnostic clarity.

| Product | Specification |

| Single-Channel ECG Paper | 50mm*20m |

| Three-Channel ECG Paper | 50mm*30m |

| 60mm*30m | |

| 63mm*30m | |

| 80mm*20m | |

| 80mm*70mm-200SHT | |

| 112mm*20m | |

| 112mm*90mm-200SHT | |

| 144mm*30m | |

| 145mm*30m | |

| 110mm*140mm-20m | |

| Six-Channel ECG Paper | 144mm*30m |

| 110mm*140mm-20m | |

| 110mm*140mm-200SHT | |

| 110mm*140mm-20m | |

| 110mm*20m | |

| Twelve-Channel ECG Paper | 210mm*30m |

| 215mm*30m | |

| 216mm*20m | |

| 145mm*100mm-200SHT | |

| 210mm*140mm-20m | |

| 210mm*140mm-200SHT | |

| 210mm*150mm-200SHT | |

| 210mm*150mm-150SHT | |

| 210mm*150mm-150SHT | |

| 210mm*295mm-200SHT | |

| 215mm*280mm-200SHT | |

| 215mm*280mm-200SHT | |

| 215mm*280mm-200SHT | |

| 210mm*300mm-200SHT | |

| 210mm*300mm-200SHT | |

| 210mm*280mm-200SHT | |

| 210mm*300mm-200SHT | |

| 144mm*125mm-200SHT | |

| 50mm*100mm-300SHT | |

| 50mm*100mm-300SHT |

Why Use an ECG Paper instead of Ordinary Paper?

The thermal paper used to manufacture ECG paper is coated with an invisible chemical substance to increase its resistance to variations in humidity and temperature. Because the records are less likely to be impacted by outside circumstances, it guarantees that the data are more reliable.

Ensuring Regulatory Compliance in ECG Paper Production

Compliance with regulatory standards governing ECG paper production, including ISO certifications and FDA approvals, is imperative to uphold product safety and reliability.

What Should I Look for in an ECG Paper?

When choosing ECG paper, prioritize size compatibility with your machine model for accurate recordings. Opt for high-quality paper with optimal density and opacity to ensure precise waveforms and minimize artifacts. Confirm compatibility with your machine to prevent operational issues. Balance cost considerations with quality for optimal performance and diagnostic accuracy.

Size Variants

Selecting the right ECG paper size is critical for accurate recordings. Various sizes, such as rolls or Z-fold ECG paper pads, cater to machine models and user preferences. Opting for the appropriate size ensures precise waveforms and ease of interpretation, enhancing diagnostic precision and efficiency.

Quality Standards

Prioritize ECG paper with high-density composition and optimal opacity to produce sharp, clear waveform tracings. Papers with superior quality are less prone to fraying or curling, minimizing artifacts that can affect diagnostic accuracy. Quality standards ensure reliable recordings are crucial for precise interpretation and clinical decision-making.

Compatibility Assurance

Ensure compatibility between the chosen ECG paper and your machine brand and model. Refer to the machine’s manual or consult with after-sale support services to confirm compatibility. Seamless integration between paper and machine enhances operational efficiency and ensures accurate waveform recordings for diagnostic accuracy and patient care.

Cost Considerations

While price is a factor, prioritize quality and reliability over cost alone. Investing in higher-priced ECG paper can yield long-term benefits by ensuring durability and accuracy, ultimately enhancing diagnostic efficacy and reducing potential errors. Balance cost considerations with quality standards to make informed purchasing decisions aligned with clinical needs and budget constraints.

Final Thoughts

The role of medical ECG paper manufacturers and suppliers is indispensable. Their commitment to precision, quality, and innovation fuels the accurate diagnosis and treatment of cardiac conditions, ultimately contributing to the well-being of patients worldwide. Through their unwavering dedication, the heartbeat of healthcare remains steady and robust, safeguarding lives with every ECG recording.

FAQs: ECG Paper

Which paper is used in ECG?

ECG paper typically consists of thermal paper sensitive to heat and pressure. This type of paper allows the ECG machine to print the heart’s electrical activity in the form of waveforms.

What is the standard paper for ECG?

The standard paper size for ECG recordings papers can vary depending on the machine and regional preferences. However, standard sizes include 50mm x 20m, 80mm x 20m, 110mm x 20m rolls, and Z-fold pads in various dimensions.

How do you read an ECG paper?

To read an ECG paper, identify the baseline representing the heart’s resting state. Then, analyze the waveforms, noting their shapes, durations, and intervals. Different waveforms indicate various aspects of cardiac activity, helping healthcare professionals assess the heart’s rate, rhythm, and abnormalities.

What size is ECG paper?

ECG paper comes in various sizes, including standard rolls and Z-fold pads. Ordinary dimensions for ECG paper rolls range from 50mm to 110mm in width and 20m to 30m in length. Z-fold pads may vary in size but typically accommodate standard ECG machine specifications.