When it comes to blood collection and preservation, the importance of EDTA tubes cannot be overstated. These tubes play a pivotal role in ensuring accurate lab results by preventing blood clotting and preserving the integrity of blood samples. But have you ever wondered what goes into making these essential medical tools?

In this blog, we’ll dive deep into the EDTA tube manufacturing process, unraveling what makes a product truly high-quality. Whether you’re in the medical industry, a lab technician, or just curious, keep reading to learn how a reliable EDTA tube manufacturer ensures excellence from start to finish.

Table of Contents

Why Are EDTA Tubes So Important?

EDTA (Ethylenediaminetetraacetic acid) is a powerful anticoagulant widely used in blood sample collection to prevent clotting. The design of these tubes specifically maintains the quality and consistency of blood samples for diagnostic testing. Without them, labs would struggle to provide reliable results for critical tests like complete blood counts (CBC).

For this reason, the manufacturing process of EDTA tubes requires precision, high-quality materials, and stringent quality control. Any compromise in quality can directly impact patient care, making it essential to choose a trusted EDTA Tubes Manufacturer like Siny Medical.

The Core Components of an EDTA Tube

Before we explore how manufacturers create EDTA tubes, let’s first understand the components that make up this essential medical tool.

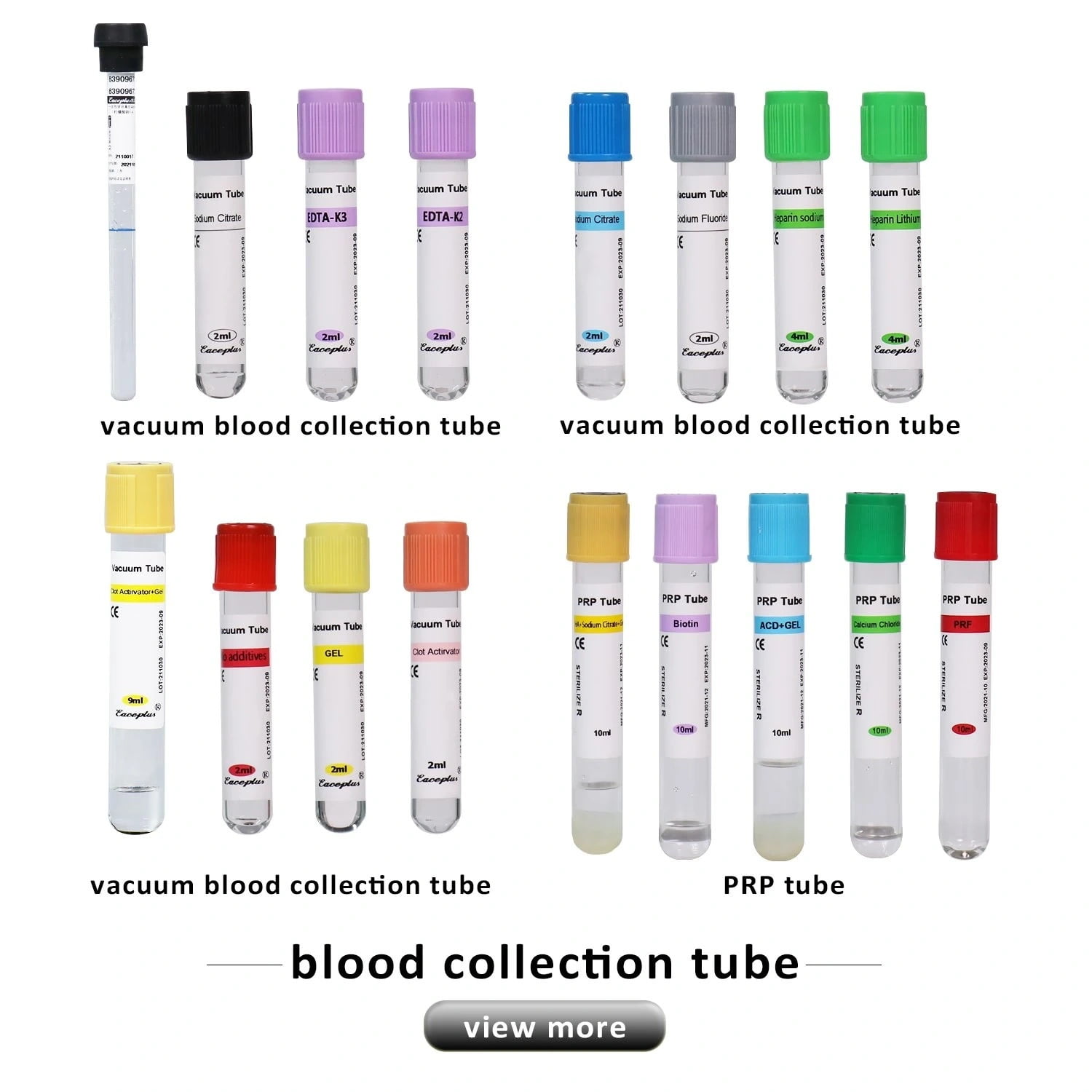

- Tube Material: Typically made of medical-grade plastic or glass, the material ensures durability, sterility, and compatibility with blood samples.

- EDTA Additive: The technician carefully coats or adds EDTA tubes supplier to the inside of the tube in a precise quantity. This additive prevents blood clotting by binding calcium ions.

- Cap and Closure: Designed for secure sealing, caps help maintain vacuum pressure and ensure contamination-free samples.

- Labeling: We mark the tubes with accurate labels for easy identification and compliance with international standards

The combination of these components ensures that the tube performs flawlessly under various lab conditions.

The Step-by-Step EDTA Tubes Manufacturing Process

Producing EDTA tubes for blood collection is a highly technical and regulated process. Here’s a detailed breakdown of the key stages:

1. Material Selection and Preparation

The first step involves sourcing high-quality raw materials. Manufacturers like Siny Medical prioritize medical-grade plastics and glass to ensure the tube’s durability and sterility. The material undergoes rigorous cleaning and sterilization to eliminate contaminants.

2. Molding and Shaping

After preparing the raw materials, manufacturers mold them into the desired shape. Advanced injection molding machines create plastic tubes, while heat and precision tools form glass tubes. This step determines the tube’s size, thickness, and overall design.

3. Coating with EDTA

This is the most critical phase of the manufacturing process. A precise amount of EDTA additive is coated onto the inner walls of the tube. The additive must adhere uniformly to ensure consistent anticoagulant performance.

Fun Fact: Siny Medical uses state-of-the-art technology to achieve this, ensuring every tube meets international standards.

4. Sealing and Capping

Secure caps fit the tubes, maintaining vacuum pressure and preventing contamination. Often, color-coded caps (e.g., lavender) allow for easy identification.

5. Quality Control Testing

Quality is paramount in medical manufacturing. Each batch of EDTA tubes undergoes rigorous testing for:

- Sterility: Ensuring no contaminants are present.

- Vacuum Retention: Verifying the tube can maintain a vacuum seal.

- Anticoagulant Efficacy: Ensuring the EDTA coating prevents clotting effectively.

Top manufacturers like Siny Medical adhere to ISO and CE certifications, which are essential for global compliance.

6. Labeling and Packaging

After passing quality checks, tubes are labeled with clear, durable markings. They are then packaged in sterile environments to prevent contamination during storage or transport.

What Sets a Reliable EDTA Tubes Manufacturer Apart?

Not all manufacturers are created equal. When choosing an EDTA Tubes Manufacturer, consider the following factors:

- Quality Standards: Ensure the manufacturer complies with ISO 13485 and other international certifications.

- Technology and Innovation: Advanced manufacturing processes result in consistent, high-quality products.

- Global Reputation: Trusted companies like Siny Medical have a proven track record of reliability and customer satisfaction.

- Customization Options: The ability to produce tubes in various sizes, capacities, and coatings.

How to Ensure Quality When Choosing EDTA Tubes

Here are a few tips to verify the quality of EDTA tubes before purchase:

- Check the Manufacturer’s Certifications: Look for compliance with ISO and CE standards.

- Request Sample Testing: Many manufacturers provide sample tubes for testing.

- Inspect the Packaging: Manufacturers package high-quality tubes in sterile, sealed environments.

- Evaluate Customer Reviews: Feedback from other buyers can provide valuable insights.

For those in the market, Siny Medical’s EDTA tubes are a standout choice, combining cutting-edge technology with rigorous quality control.

Wrapping It All Up

The EDTA tubes manufacturing process is a fascinating blend of science, technology, and meticulous attention to detail. From sourcing high-quality materials to ensuring compliance with international standards, every step plays a vital role in producing a reliable product.

When it comes to choosing a trusted EDTA Tubes Manufacturer, Siny Medical stands out as an industry leader. With their advanced technology, strict quality control, and customer-centric approach, they provide medical professionals with the tools they need to deliver accurate results.

Whether you’re a healthcare provider, a lab technician, or someone interested in medical technology, understanding the manufacturing process of EDTA tubes offers valuable insights into how these small tools make a big difference. Want to learn more or place an order? Contact Siny Medical today!

FAQs EDTA Tubes and Manufacturing

Q: What is the role of EDTA in blood collection tubes?

A: EDTA is an anticoagulant that prevents blood samples from clotting, ensuring accurate lab results.

Q: Why is quality control critical in EDTA tube manufacturing?

A: Quality control ensures that the tubes are sterile, durable, and perform as expected under lab conditions.

Q: Can EDTA tubes be customized?

A: Yes, manufacturers like Siny Medical offer customization options for size, capacity, and additive concentration.

Q: How do I store EDTA tubes?

A: Store them in a dry, cool place, away from direct sunlight, to maintain sterility and vacuum pressure.

Q: What makes Siny Medical a trusted EDTA Tubes Manufacturer?

A: Their commitment to quality, innovation, and global compliance sets them apart in the medical industry.

You May Also Read

- Top 5 Lab Tests That Require EDTA Tubes

- A Complete Guide to EDTA Tubes: Types, Uses, and Benefits

- The Purple EDTA Tube in the Blood Collection Tube

- The Differences EDTA K2 vs EDTA K3 Blood Collection Tubes

- Why EDTA is Used as the Additive in Purple Top Tubes?

If you enjoyed this article, please subscribe to our YouTube channel. We provide product video tutorials. You can also follow us on Instagram and Facebook to stay up to date with new updates, news and special deals.