A blood bag is a sterile, flexible container for collecting, storing, and transporting blood and its components. It is typically made of plastic and is designed to prevent contamination and maintain the integrity of the blood product. Blood bags are used in blood banks, hospitals, and other healthcare settings for various purposes, including blood transfusions, blood donations, and laboratory testing. They are available in different sizes and configurations, depending on the specific needs and requirements of the medical facility.

Table of Contents

- 1 What is a blood bag?

- 2 Benefits of Blood Bags

- 3 How Blood Bags are Manufactured

- 4 Finding the Right Blood Bag Manufacturer

- 4.1 Research and identify potential manufacturers

- 4.2 Evaluate their certifications and compliance

- 4.3 Assess their production capabilities

- 4.4 Quality control and testing procedures

- 4.5 Request samples and evaluate product quality

- 4.6 Consider pricing and cost-effectiveness

- 4.7 Check for references and customer reviews

- 5 Summary

- 6 FAQs:

- 6.1 How are blood bags sterilized before use?

- 6.2 Common materials used in blood bag manufacturing include PVC (polyvinyl chloride) and polyolefins?

- 6.3 How do regulatory bodies ensure the safety of blood bag products?

- 6.4 What role do blood bag manufacturers play in addressing transfusion-related risks?

What is a blood bag?

A blood bag is a sterile container for collecting, storing, and transfusing blood and its components. It is typically made of plastic and includes anticoagulants and preservatives to ensure the safety and viability of the blood.

A blood bag is a specialized container used in healthcare settings to safely collect, store, and transport blood and blood components.

This is a single-use medical transparent flexible polyvinyl chloride (PVC) container for the collection, processing, and storage of whole blood and blood components.

| Item | Options |

|---|---|

| Anticoagulant | CPDA-1, CPD+SAGM |

| Type | Single Blood Bag, Double Blood Bag, Triple Blood Bag, Quadruple Blood Bag |

| Satellite | 1200mL, 1300mL, 2200mL, 2300mL, 3*300mL |

| Needle | 16G |

| Capacity | 200ml, 250ml, 350ml, 400ml, 450ml, 500ml |

Benefits of Blood Bags

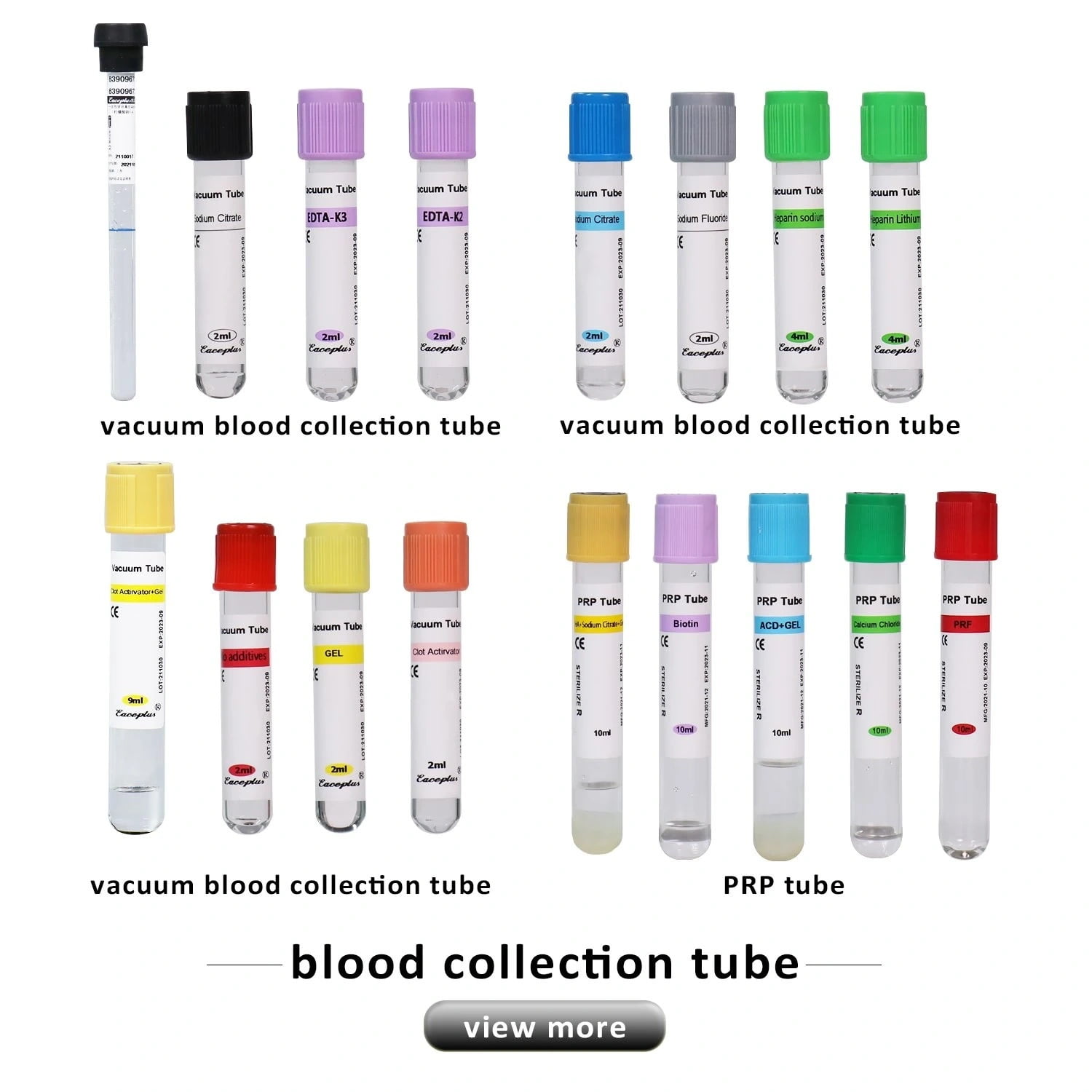

Several types of blood bags are used for blood collection and storage. Some common types include:

Single blood bag

This is the most basic type of single blood bag used for collecting and storing a single unit of blood. It typically consists of a plastic bag with an anticoagulant solution and a needle attached for blood collection.

Double Blood Bag

This type of double blood bag is used for collecting and storing two units of blood. It consists of two compartments within a single bag, allowing for the separation of blood components during collection.

Triple blood bag

Like the double blood bag, the triple blood bag collects and stores three blood units. It has three compartments within a single bag, allowing for the separation of different blood components.

Quadruple blood bag

This type of quadruple blood bag collects and stores four units of blood. It consists of four compartments within a single bag, allowing for the separation of different blood components.

Satellite bag

Primary blood bags utilize satellite bags to collect and store additional blood components. These bags attach to the primary bag and have the capacity to collect plasma, platelets, or other blood components.

Transfer bag

Transfer bags transfer blood or blood components from one bag to another. Blood bags often use during blood component processing and designed to prevent contamination or mixing of different blood components.

How Blood Bags are Manufactured

Manufacturers carefully control and maintain a sterile environment to produce blood bags, ensuring the safety and quality of the final product.

The manufacturing process typically involves the following steps:

1. Selection of raw materials: The main component of blood bags is medical-grade plastic, usually made of polyvinyl chloride (PVC) or polyolefin. The plastic sheets must be high quality and meet the required safety standards.

2. Plastic extrusion: These tubes will form the main body of the blood bag. The manufacturing process melts the selected plastic sheets and extrudes them into long, continuous tubes.

3. Tube cutting and sealing: The manufacturer cuts the continuous tubes into appropriate lengths, depending on the desired size of the blood bag. Then, they seal the ends of the tubes to create a closed system.

4. Tube welding: The main body of the blood bag welds additional tubes to serve as access points for filling and emptying the bag. These tubes also seal to maintain a closed system.

5. Sterilization: Blood bag manufacturers subject the blood bags to a sterilization process, such as gamma irradiation or ethylene oxide gas, to eliminate potential pathogens or contaminants.

6. Quality control: The manufactured blood bags undergo rigorous quality control checks to meet the required standards. This includes testing for integrity, leak resistance, and compatibility with blood components.

7. Packaging: Blood bag manufacturers subject the blood bags to a sterilization process, such as gamma irradiation or ethylene oxide gas, to eliminate potential pathogens or contaminants.

Finding the Right Blood Bag Manufacturer

Finding the right blood bag manufacturer is crucial for ensuring the safety and quality of blood products.

Here are some steps to help you find the right blood bag manufacturer:

Research and identify potential manufacturers

Research and identify potential blood bag manufacturers. Look for manufacturers that specialize in producing medical-grade bags and have experience in the healthcare industry.

Evaluate their certifications and compliance

Check if the manufacturer has the necessary certifications and compliance with regulatory bodies such as the FDA (Food and Drug Administration) in the United States or the European Medicines Agency (EMA) in Europe. These certifications ensure that the manufacturer follows strict quality control standards.

Assess their production capabilities

Evaluate the manufacturer’s production capabilities and capacity to meet your requirements. Consider factors such as production volume, lead time, and ability to customize the blood bags according to your specifications.

Quality control and testing procedures

Inquire about the manufacturer’s quality control and testing procedures. They should have stringent quality control measures to ensure the blood bags’ safety and integrity. Ask for details about their testing protocols and certifications.

Request samples and evaluate product quality

Request samples from the shortlisted manufacturers and evaluate the quality of their blood bags. Pay attention to material durability, leak resistance, and ease of use.

Consider pricing and cost-effectiveness

Obtain quotes from the manufacturers and compare their pricing. However, remember that the cost should not be the sole determining factor. It is important to balance cost-effectiveness with quality and reliability.

Check for references and customer reviews

Ask for references from the manufacturer and contact their existing clients to gather feedback about their experiences.

We are manufacturers and suppliers of wholesale Medical consumables. In addition, we offer customizable services. Siny Medical can meet your needs. If you need medical consumables manufacturers and suppliers, please contact us.

Summary

Blood bag manufacturers play a vital role in supporting healthcare systems globally by providing essential equipment for blood transfusion. Through innovation, adherence to strict quality standards, and collaboration with regulatory authorities and healthcare providers, these manufacturers contribute to the safe and effective delivery of blood products to patients in need.

FAQs:

How are blood bags sterilized before use?

Blood bags undergo sterilization through gamma irradiation or ethylene oxide gas treatment to ensure they are contaminant-free.

Common materials used in blood bag manufacturing include PVC (polyvinyl chloride) and polyolefins?

The most commonly used materials are PVC (polyvinyl chloride) and polyolefins because they exhibit compatibility with blood components and sterilization processes.

How do regulatory bodies ensure the safety of blood bag products?

Regulatory bodies such as the FDA and EMA establish and enforce strict standards for blood bag manufacturing, including rigorous testing and inspection protocols.

What role do blood bag manufacturers play in addressing transfusion-related risks?

Manufacturers develop specialized features such as filters and anticoagulants to minimize the risk of transfusion reactions and ensure the safe administration of blood products.