In order to reduce the labour intensity of medical personnel and the probability of occurrence of medical accidents, this paper designed a kind of packaging equipment suitable for labelling disposable blood vessels. The team analyzed the movement form of the disposable blood vessel labeling system, determined its process flow, and designed its overall structure. This design primarily includes the conveying mechanism and the labeling mechanism for the blood-collecting vessels. This version emphasizes the actions taken by the team, making it more direct and engaging.

The designed vessel conveying mechanism can effectively realize the conveying and unscrambling work of the disposable blood vessels, and the labelling mechanism can paste self-adhesive labels accurately and quickly to guarantee the reliability of the whole machine. Moreover, the equipment has a small floor area requirement and high practicability and has a more significant value of extensive application.

Table of Contents

Introduction

The labelling machine is used to stick labels on products or specified packaging. Packaging machinery and equipment is an indispensable component of modern packaging machinery. Currently, most of the blood collection tube labelling equipment is industrial grade. Although the efficiency is high, the equipment is large and mainly functions to collect blood. The factory labels the tube with information specific to the blood collection tube itself.

Medical staff can attach patient personal information to a few small-sized blood collection tubes after blood collection.

In traditional blood collecion activities, the medical staff usually handwrites or pre-prints the patient’s information on the label. Medical staff manually paste the self-adhesive barcode containing the patient’s information onto a disposable blood collection tube, making the process labor-intensive, inefficient, and prone to errors.

Process design of disposable blood collection tube labeling system

The characteristics of disposable blood collection tubes

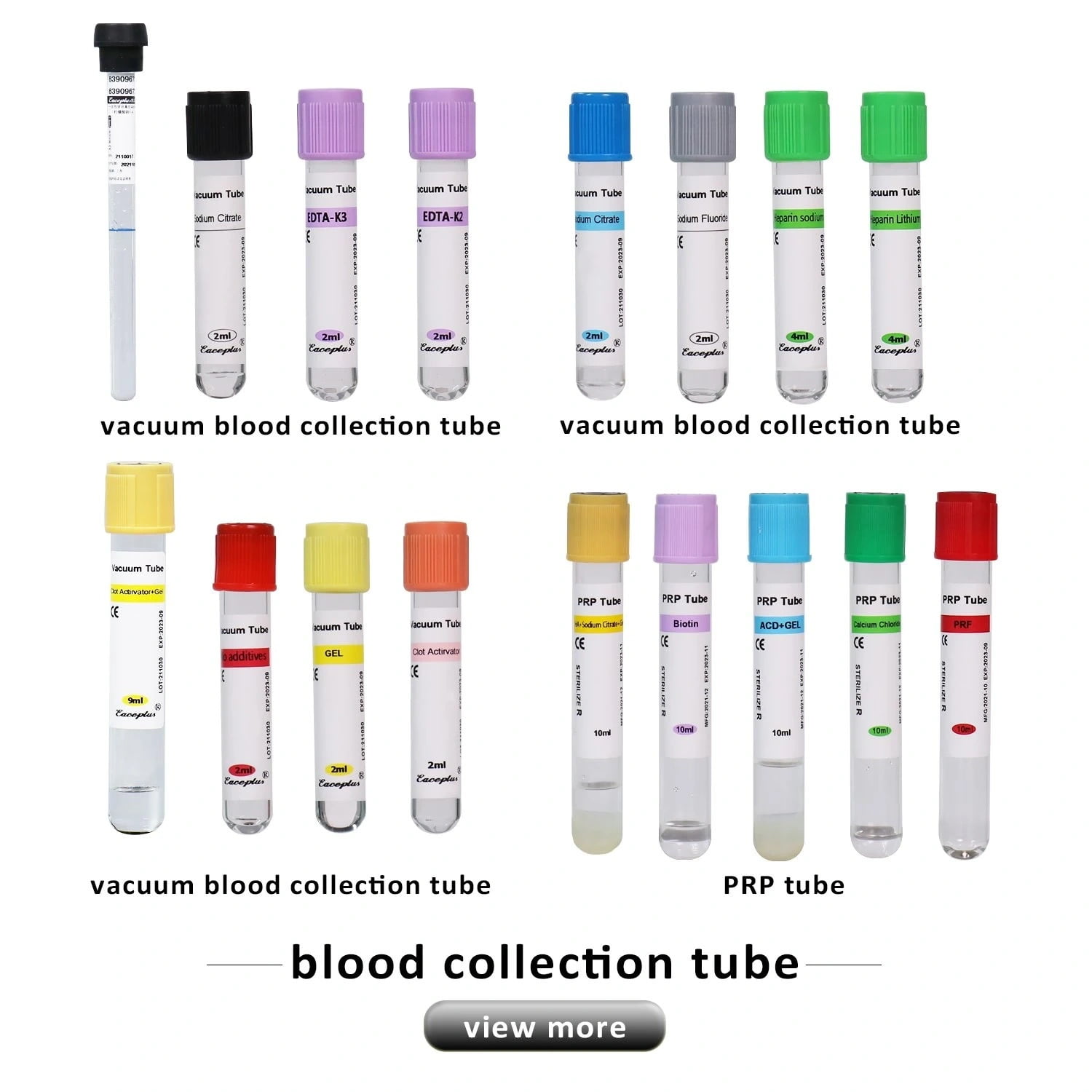

Currently, manufacturers produce most medical blood collection tubes as vacuum blood collection tubes made from PET (polyethylene terephthalate) plastic. This design effectively prevents impact vibrations during transport from causing the tube wall to rupture and blood samples to spill, thereby reducing the likelihood of sampling errors. The discarded test tubes are easy to recycle and reuse. A vacuum blood collection tube is a vacuum negative pressure blood collection tube. Different colours are divided into various categories to hold different needs

The blood samples are processed differently and divided into different sizes according to their capacity.

Specifications

The most widely used is an ml blood collection tube with a total length of 80 mm, tube length75 mm, tube diameter13 mm, cap length15 mm, cap diameter16 mm, and screw-on length10. This article is based on the MLA labelling machine designed using blood collection tubes.

Because medical staff draw blood intermittently

The blood collection tube labeling system uses intermittent motion, and medical personnel operate it. After the staff completes the blood draw, they put the blood collection tube in the corresponding position and start the switch. Send a pulse signal, and the motor rotates the corresponding angle to achieve intermittent operation movement.

At the same time, we adopted a turntable structure to reduce the size of the entire machine, considering the labeling system’s actual working environment. The main motion form of the vascular labelling system is intermittent rotational motion.

Information reliability analysis

Information transfer mainly includes information printing and label pasting. The printing device adopts a non-contact inkjet printing device, using Piezoelectric inkjet technology, due to the printing process produced by piezoelectric inkjet technology. To save costs, we separate the ink cartridges and print heads, using the ink tube to transport ink. Based on the working environment of blood collection, we select roll-type self-adhesive labels as the label paper. This version emphasizes the actions taken and makes the sentences more direct and engaging. The self-adhesive label has an excellent labelling effect, and the equipment has no glue smell diffusion, which is suitable for Places with high hygiene requirements, such as medicine and food.

Accuracy of Information

After the computer identifies the patient’s personal information through the medical card, The printing device prints the corresponding barcode information on the self-adhesive label. We attach the label after placing the disposable blood collection tube in the designated position, ensuring that the patient’s information corresponds accurately to the blood sample.

Process analysis

The process flow of the disposable blood collection tube labelling system is shown in figure1.

Disposable blood collection tube labeling system process flow

The system delivers the blood serum tube to the designated location, then sorts and applies a printed label with the patient’s information. The delivery device should have good clamping and positioning of the blood collection tube and the labelling device.

Structural design of disposable blood collection tube labeling system

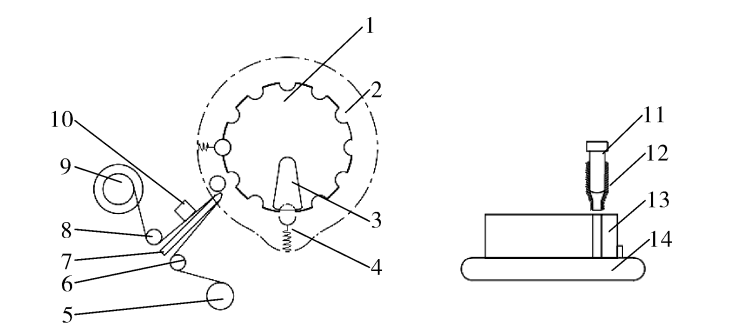

The structure of the disposable blood collection tube labelling system. The system mainly includes:

- A blood collection tube transfer mechanism.

- Labelling mechanism.

- Blood collection tube collection mechanism.

- Three parts of the organization.

The blood collection tube transfer mechanism mainly includes a central turntable, a fixed cam bracket, a separation cam, a blood collection tube clamp, etc.

which completes the clamping, transfer and release of disposable blood collection tubes. The labelling mechanism mainly includes a paper receiving tray, a paper guide roller, a peeling plate, a label placing tray, a printing device, etc., which completes the printing of patient information and label transfer. The blood collection tube storage mechanism mainly includes a blood collection tube rack fie belt is used to complete the storage process of disposable blood collection tubes

1-Center turntable,

2-Fixed bracket cam,

3.-Separation cam,

4.-Blood collection tube clamp,

5-Paper collection tray,

6,8-Paper guide roller,

7-Stripboard,

9-Place the label plate,

10-Printing device,

11-Blood collection tubes,

12-Blood collection tube support frame,

13-Blood collection tube rack,

14-Positioning belt.

One station to complete labelling in one cycle.

The paper receiving tray and label roller rotate simultaneously, And the printed label containing the patient information is rolled onto the disposable. On the blood vessel and disposable blood collection tube (before labelling), turn to the labelling station.

At the same time as the labelling station, the disposable blood collection tubes at the original labelling station are transferred to the outlet. At this time, the tube clamp of the blood collection tube gradually opens, and the blood collection tube is After the tube falls into the blood collection tube rack on the positioning belt, the positioning belt rotates. Move a station to complete the storage of blood collection tubes and the subsequent blood collection tube Receiving preparation.

The overall structure of the disposable blood collection tube labeling system

After medical personnel complete the blood collection operation, they place the 10ml disposable blood collection tube into the slot of the center turntable, ensuring continuous workflow.

Schematic diagram of the disposable blood collection tube labeling system

1-Motor,

2-Active pulley,

3-Positioning belt,

4-Blood collection tube rack,

5-Driven pulley,

6-Fixed bracket cam,

7-Place the label plate,

8-Paper guide roller,

9-Printing device,

10-Label roller,

11-Stripboard,

12-Center turntable,

13-Separation cam,

14-Spindle,

15-Paper collection tray,

16-Blood collection tube clamp.

Start the motor, rotate it to the corresponding angle, and rotate the disposable blood collection tube rotatesto the labelling station. At this time, the labelling motor rotates, the label paper is fed from the label tray, and the peeling plate peels the label off through the paper guide roller. The device prints the patient information on the label paper in advance, and the label roller is Responsible for smoothing the label and driving the disposable blood collection tube to rotate the Labeling; the paper tray recycles the bottom paper. The center turntable rotates to the discharge station while the fixed bracket convex clamps the blood collection tube. The wheel opens, and the disposable blood collection tube falls into the blood collection tube.

The tube clamp is open and closed

When the material is in the working position, the spring is compressed

The fixed bracket cam6Under the action of along the rail, move outwards to move slot-7 and fix slot-8.

At the next station, the fixed bracket cam opens the compressed spring. The cam then compresses the spring, closing the blood collection tube clamp again.

Labeling Mechanism

The labelling mechanism is equipped with the following:

- Inkjet Printing Device: A non-contact printer transfers patient data onto self-adhesive labels. This method allows precise, legible labelling that adheres to high hygiene standards.

- Label Application Rollers: The system applies labels efficiently using a roller mechanism, which ensures the label attaches without wrinkles or displacement.

- Self-Adhesive Label Roll: Self-adhesive labels eliminate the need for glues or adhesives that could affect healthcare environments.

Collection Mechanism

Once labelled, tubes are directed to a collection area:

- Rack System: Tubes are stored in racks for organized, safe transport.

- Buffer Cushions: These are used in the rack slots to absorb impact, preventing damage to the tube or sample.

Benefits of an Automated Labeling System

Automating the labelling process in medical settings comes with numerous benefits:

- Reduction in Manual Labor: Medical personnel save time and energy, as the system requires minimal manual intervention.

- Increased Labeling Accuracy: Automated labeling ensures that identifying information correctly matches patient samples, reducing human error.

- Enhanced Speed and Efficiency: The system speeds up the labelling process by automating tasks, allowing for faster patient handling and turnaround times.

Labeling Process Flow

The labelling process involves several sequential steps:

- Tube Placement on Turntable: Place the tube in a designated slot on the rotating turntable.

- Labelling Station: The labeling device aligns with the tube, prints the information, and applies the label.

- Verification: Each label is verified against the patient data for accuracy.

- Collection in Rack: Labeled tubes move to the collection rack for organized storage.

Conclusion

The design of a disposable blood collection tube labelling system offers a breakthrough in healthcare operations by automating a traditionally manual, error-prone task. This system enhances efficiency, accuracy, and safety in blood sample handling through thoughtful design, engineering, and medical-grade materials. As the demand for automation grows in healthcare, such innovations will continue to drive improvements in patient care and operational effectiveness, setting a new standard for managing Siny medical samples.

FAQs

How does this system improve patient safety?

- The system automates labeling to ensure each tube accurately displays the patient’s details, reducing the risk of errors that may lead to misdiagnosis.

What is the capacity of this system?

- The system can handle multiple tubes in quick succession, with intermittent rotation that fits various operational demands without requiring constant manual intervention.

Is this system compatible with different blood tube sizes?

- Yes, while the system optimizes for the 3 mL blood tube, it also adjusts to fit different tube dimensions within standard medical sizes.

What materials are used to ensure hygiene?

- The system uses medical-grade materials compatible with hospital hygiene requirements, and the adhesive labels do not emit odors.

How does it connect with patient data systems?

- The system integrates with electronic health records (EHRs) to directly transfer data from the patient’s record to the label.

Can this system be used in small clinics?

- Absolutely. Its compact design makes it suitable for both large hospitals and small clinics.

You May Also Read

- Best Blood Collection Tubes for PRP

- Types of Blood Collection Tubes and Their Uses

- What is a Serum Blood Collection Tube?

- How to use a Micro Blood Collection Tube to Collect Blood?

- The Power of Sodium Citrate Blood Collection Tubes

- The Materials and Additives used in Vacuum Blood Collection Tubes

- A Guide to Choosing Quality Blood Collection Tubes

If you enjoyed this article, please subscribe to our YouTube channel. We provide product video tutorials. You can also follow us on Instagram and Facebook to stay up to date with new updates, news and special deals.