Medical and diagnostic laboratories use the blood collection tube manufacturing process as essential tools for collecting and storing blood samples. These tubes play a crucial role in maintaining the integrity and quality of blood samples, ensuring accurate and reliable test results. The manufacturing process of blood collection tubes involves several steps, each contributing to the overall functionality and safety of the tubes. This article will explore the seven essential steps involved in the blood collection tube manufacturing process.

Table of Contents

Step 1: Glass Tube Production

In this initial step, manufacturers produce high-quality glass tubes that serve as the primary material for manufacturing blood collection tubes. Additionally, manufacturers conduct thorough quality control on the glass tubes to ensure their durability and integrity. Furthermore, they use precision techniques to manufacture the glass tubes, ensuring uniform dimensions and smooth surfaces. Moreover, the use of such precision techniques guarantees that the final blood collection tubes meet the highest standards of quality and reliability.

Step 2: Tube Cleaning and Surface Treatment

After producing the glass tubes, they undergo a meticulous cleaning and surface treatment process. This step involves washing the tubes with specialized cleaning agents to remove contaminants or impurities. Manufacturers subject the tubes to surface treatment, such as silanization, to enhance their compatibility with the collection additives.

Step 3: Additive Application

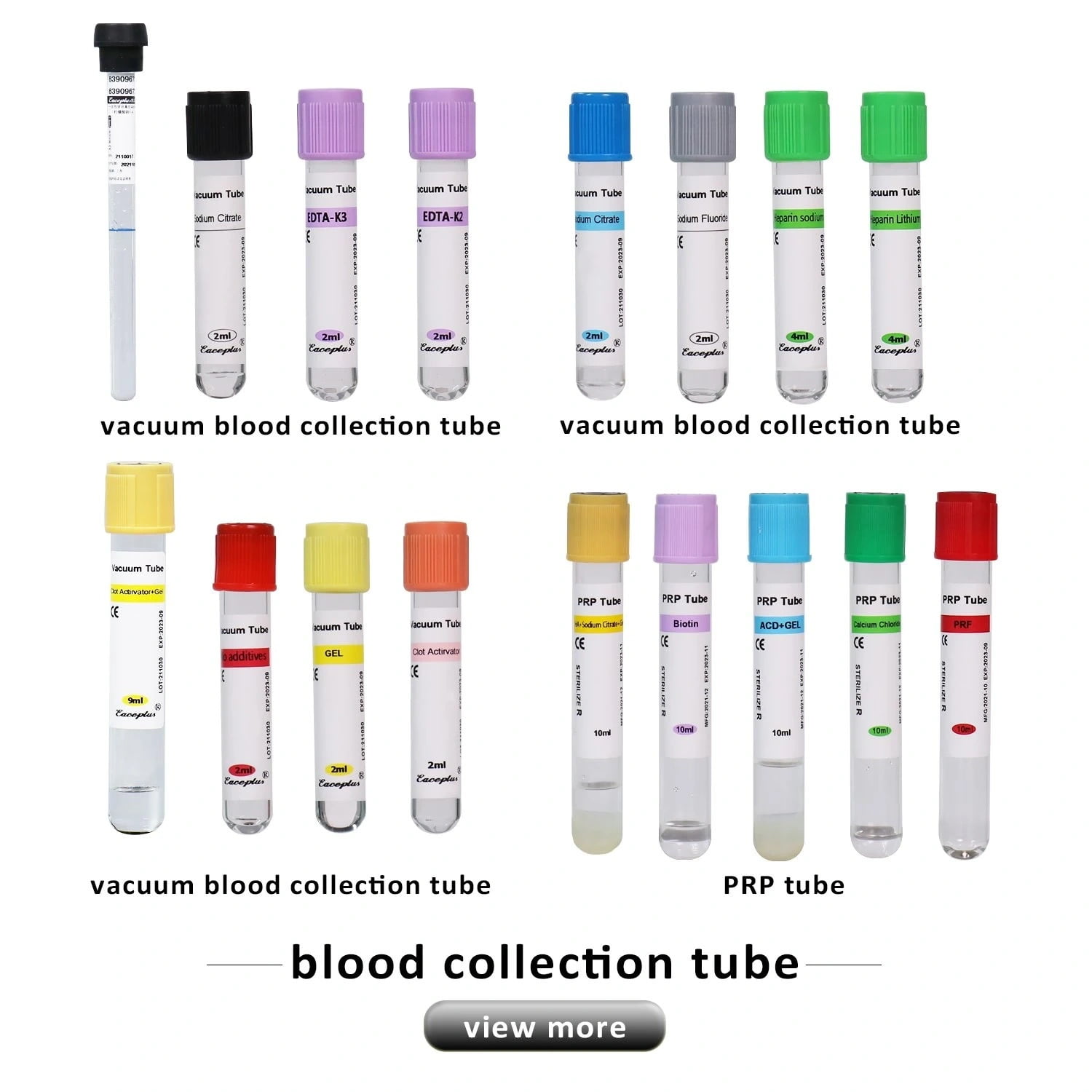

Additives play a crucial role in blood collection tubes as they help preserve the integrity of blood samples and prevent clotting. In this step, manufacturers apply the appropriate additives to the interior of the tubes. These additives may include anticoagulants, clot activators, gel separators, or preservatives, depending on the specific requirements of the intended tests.

Step 4: Tube Sealing

The tubes undergo a sealing process to ensure the integrity and safety of the blood samples. Manufacturers securely seal the top of the tube using various methods, such as heat sealing or stopper insertion. This step prevents any leakage or contamination during transporting and storing of blood samples.

Step 5: Vacuum Creation

Some blood collection tubes require the creation of a vacuum inside the tube. This vacuum, in turn, helps draw a precise amount of blood into the tube and facilitates the separation of serum or plasma from the cellular components. Additionally, manufacturers employ specialized machinery to carefully control the pressure inside the tube, thus creating the necessary vacuum.

Step 6: Tube Labeling and Printing

Proper labeling and printing of blood collection tubes are crucial for accurate sample identification and traceability. In this step, manufacturers label the tubes with essential information, including patient details, collection date, and tube type. They may also add barcodes or QR codes to facilitate automated tracking and processing of the samples.

Step 7: Packaging and Sterilization

In the final step of the blood collection tube manufacturing process, the tubes are carefully packaged to ensure their safety during transportation and storage. Manufacturers design the packaging materials to protect against breakage or damage. Additionally, the tubes may undergo a sterilization process to eliminate any potential contaminants and maintain the sterility of the samples.

Conclusion

The manufacturing process of blood collection tubes involves a series of precise steps to ensure these essential medical tools’ quality, functionality, and safety. From glass tube production to sealing, labelling, and packaging, each step is crucial in maintaining the integrity of blood samples and obtaining accurate diagnostic results. By understanding the manufacturing process,

Frequently Asked Questions:

Why are blood collection tubes essential in medical laboratories?

Blood collection tubes are crucial in medical laboratories as they facilitate collecting, storing, and analysing blood samples for diagnostic purposes. These tubes help maintain the integrity of blood samples and ensure accurate test results.

What materials are blood collection tubes made of?

Manufacturers primarily use high-quality glass to make blood collection tubes. Manufacturers design the glass used to be durable, transparent, and compatible with the collection additives. Some specialized tubes may also use plastic materials.

What are additives in blood collection tubes?

Manufacturers add substances called additives to blood collection tubes to aid in preserving and processing blood samples. They may include anticoagulants to prevent clotting, clot activators for specific tests, gel separators to separate serum or plasma, or preservatives to maintain sample stability.

How are blood collection tubes sealed?

Manufacturers use various methods, such as heat sealing or stopper insertion, to seal blood collection tubes. These sealing techniques ensure secure closure of the tubes, preventing leakage or contamination of the blood samples.

What is the purpose of creating a vacuum inside some blood collection tubes?

The vacuum inside certain blood collection tubes helps facilitate the precise collection of blood and aids in separating serum or plasma from the cellular components. The vacuum ensures accurate test results and proper sample handling.

Can blood collection tubes be reused?

No, blood collection tubes are designed for single use only. Reusing the tubes can lead to contamination, compromised test results, and potential health risks. It is essential to use new, sterile tubes for each blood collection.

How are blood collection tubes labeled and tracked?

Manufacturers label blood collection tubes with essential information, including patient details, collection date, and tube type. They also add barcodes or QR codes to facilitate automated tracking and processing of the samples in the laboratory information system.

Are blood collection tubes sterilized before use?

Yes, blood collection tubes undergo a sterilization process to eliminate potential contaminants. Sterilization ensures the tubes are free from microorganisms, maintaining the sterility of the samples and preventing any unwanted infections.

Are there different types of blood collection tubes for specific tests?

Manufacturers design different types of blood collection tubes specifically for various tests. Each tube type contains specific additives or coatings to meet the requirements of different diagnostic tests, such as coagulation studies, chemistry panels, or blood cell counts.

How should blood collection tubes be stored?

Blood collection tubes manufacturers typically store the tubes in a controlled environment, which is usually at room temperature. Moreover, it is essential to protect them from extreme heat, direct sunlight, or freezing temperatures, as these can affect the integrity of the additives and compromise the sample quality. In addition to that, maintaining the appropriate storage conditions ensures the reliability and accuracy of the collected blood samples.

Always consult your healthcare provider or laboratory professionals for specific guidelines and recommendations regarding blood collection tube usage.